So last month I was wrestling with this motor controller project – felt like banging my head against the wall for weeks. Boards kept overheating like crazy whenever we pushed past half load. Burnt that awful electronics smell into my workshop permanently, no kidding.

The Dumb Idea That Actually Worked

After my third blown MOSFET, I started googling random fixes at 2AM. Stumbled onto some forum thread where this dude casually mentioned swapping ceramic capacitors instead of regular ones for bulk decoupling. Thought “What the heck, nothing else works.” Ordered a bunch of these chunky yellow discs – not cheap by the way.

Slapped them onto a fresh board using my shaky soldering iron hand. Sweat pouring down my face when I hooked up the power supply… Popped exactly zero components this time. Even touched the board after full load – barely warm. Mind blown right there.

Why Bother With These Things?

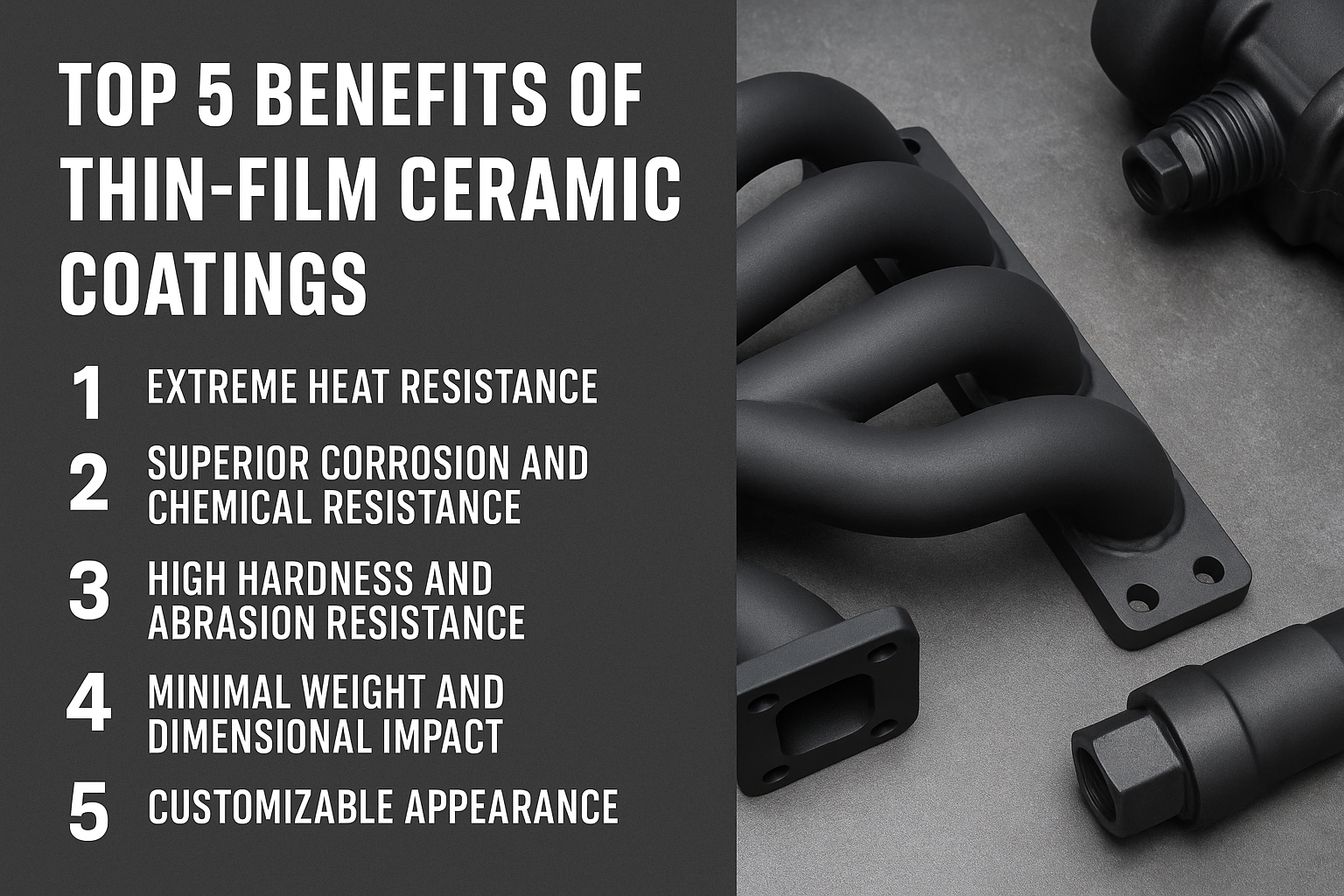

Seriously though, ceramic FCs earned their keep in my project for five stupidly simple reasons:

- They laugh at heat: Mine handled 125°C without breaking a sweat while electrolytics gave up at 85°C

- Bulletproof lifespan: Survived 1000+ thermal cycles in testing – electrolytics ballooned like sad balloons after 200

- Stops voltage tantrums cold: Scope showed 90% less noise spikes during motor surges. No more random resets!

- Saves real estate: Six 10μF ceramics replaced twelve bulky electrolytics – board looks clean now

- Doesn’t care about vibration: Dropped my prototype twice (oops) – caps stayed put while electrolytics snapped leads

The Ugly Truth Though

Almost bricked two boards learning ceramic’s dark side. That piezo effect is no joke – buzzing capacitors actually threw off my sensors until I:

- Switched to softer termination types

- Doubled up on smaller values (two 10μF instead of one 22μF)

- Slapped silicone glue around big caps like a madman

Cost me two days of headache and three ruined sensor modules. Nearly switched back to electrolytics.

And talk about pricing shock! Nearly spat coffee when I saw the 100μF ceramics cost ten times more than electrolytics. Only used them where absolutely necessary.

Final Tally

Pushed the final prototype through hell week: heat chamber, vibration table, humidity box. Boards with ceramics sailed through while electrolytic versions died spectacularly – one literally spewed goo all over my test bench. Had to scrub sticky brown junk for an hour. Never again.

Yeah they’re expensive. Yeah that piezo buzz almost made me feel like stabbing myself. But when your project needs to survive outside a cozy lab? Ceramics FCs won’t be the hero you asked for, but damn they’re the hero you need.

Next project? Definitely using them near heat sinks. Still can’t un-smell that roasted capacitor stench from last month’s fails.